I hosted a seminar this morning along with Northrop Grumman’s Dennis Pikop on the topic of how to implement and mature business process and other frameworks. We used examples that highlighted three circumstances; withing ‘legacy’ businesses that merge or acquire (Northrop Grumman), from the top downward (UPS) and from the bottom up (ThyssenKrupp Steel USA). If you missed the webinar, you can listen to a recording here. Most of our observations came from the work done for the APQC Frameworks Study, led by APQC’s John Tesmer, who was also on hand for the seminar. You can download a free copy of the APQC Frameworks Study here.

Frameworks in legacy environments

Customers often ask how to get started with frameworks such as APQC’s PCF. Not everyone has the benefit of UPS’ significant focus on process (it is simply put, the only thing they do), or the green fields approach that TKS used when they built a $5B steel plant that just opened in December 2010. Ask around…you’ll hear from most business process people that it isn’t easy to convince an underway, profitable business that a framework would provide a common vocabulary for business from the day 1, and would gradually increase in value as it matures to the point that an enterprise can have process excellence at the heart of its strategy and goals. Some would say, “Impossible.”

Customers often ask how to get started with frameworks such as APQC’s PCF. Not everyone has the benefit of UPS’ significant focus on process (it is simply put, the only thing they do), or the green fields approach that TKS used when they built a $5B steel plant that just opened in December 2010. Ask around…you’ll hear from most business process people that it isn’t easy to convince an underway, profitable business that a framework would provide a common vocabulary for business from the day 1, and would gradually increase in value as it matures to the point that an enterprise can have process excellence at the heart of its strategy and goals. Some would say, “Impossible.”

A success story

Today, Dennis showed us that Northrop Grumman has come quite a ways on the journey while going through significant mergers and acquisitions (TRW, most recently), and that their secret sauce was to make it “leader-supported but do-er empowered.” Neither executive support nor end user input alone is enough. It takes strong leadership and mass adoption for a framework to be implemented effectively and then matured. Most of all, he advised participants to appreciate the journey as it will likely take time.

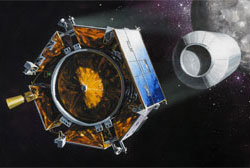

From my own experience in working with them for the past couple of years, Northrop Grumman has a remarkable level of maturity when it comes to frameworks and process through their adaptation of an APQC-like hierarchy that they call, simply, the Process Architecture. It allows this very large enterprise (over 130,000 employees) to find the common ground for their global supply chain, for example, while enabling fast-moving, innovative work such as the LCROSS space system that successfully impacted the moon, as designed, in October 2009. The fact that a large defense contractor very quickly brought together the resources and methods for a fast, experimental-but-inexpensive project is a testimony to their ability to flex their business while maintaining long-term programs like the F/A-18, ship building and more classic space vehicles. The fact they won awards for doing it was just icing on the cake.

From my own experience in working with them for the past couple of years, Northrop Grumman has a remarkable level of maturity when it comes to frameworks and process through their adaptation of an APQC-like hierarchy that they call, simply, the Process Architecture. It allows this very large enterprise (over 130,000 employees) to find the common ground for their global supply chain, for example, while enabling fast-moving, innovative work such as the LCROSS space system that successfully impacted the moon, as designed, in October 2009. The fact that a large defense contractor very quickly brought together the resources and methods for a fast, experimental-but-inexpensive project is a testimony to their ability to flex their business while maintaining long-term programs like the F/A-18, ship building and more classic space vehicles. The fact they won awards for doing it was just icing on the cake.

Northrop Grumman is able to use a framework of process to draw together common areas of their business, like design or purchasing, and to allow those areas to flex within boundaries to meet the needs of highly diverse projects. When you see what they’ve done, you begin to realize the power of frameworks and the way it has liberated what could easily be a very stodgy business model. As defense budgets draw down and projects become smaller and more frequent than in the past, Northrop Grumman is well-positioned to be highly competitive with companies that don’t have the benefit of strongly supported, highly adopted process frameworks.

Companies that don’t start the on the journey now will be playing catch up before they know it, and with competitors that will be moving ever higher in maturity level.

All Things D

All Things D ARS Technica

ARS Technica Engadget

Engadget GigaOM

GigaOM Mashable

Mashable TechCrunch

TechCrunch The Verge

The Verge Venture Beat

Venture Beat Wired

Wired Chris Brogan

Chris Brogan Brian Solis

Brian Solis Chris Dixon

Chris Dixon Clay Shirky Blog

Clay Shirky Blog HBR Blog

HBR Blog IT Redux

IT Redux Jeremiah Owyang

Jeremiah Owyang Radar O'Reilly

Radar O'Reilly Seth Godin Blog

Seth Godin Blog SocialMedia Today

SocialMedia Today Solve for Interesting

Solve for Interesting The TIBCO Blog

The TIBCO Blog Lifehacker

Lifehacker